Earlier this month we began shipping FarmBot Genesis and Genesis XL v1.8 kits to new customers. We’ve been fulfilling pre-orders on a first-in, first-out basis, and as of today we are through our backlog of orders up until about May 20th. The lead time for new orders placed today is about 3 weeks.

As you might imagine, the chaotic US tariff situation caused significant disruption and forced us to rework parts of our supply chain and shipping logistics at the last minute. I thank all of our pre-order holders for their patience as we navigated this tricky time. I’m hopeful things will become more stable in the months to come, but in the meantime we at least have enough inventory to last through the year.

So, here’s the highlights of what’s new in the v1.8 release:

Packaging

As you can see from the photo above, FarmBot Genesis and Genesis XL v1.8 are now packaged and shipped in a single box. This consolidation, along with other weight saving changes made throughout the kit, has significantly reduced the amount of single-use materials needed to package the product, reduced overall kit volume, and lowered total shipping weight by approximately 20% compared to v1.7 kits.

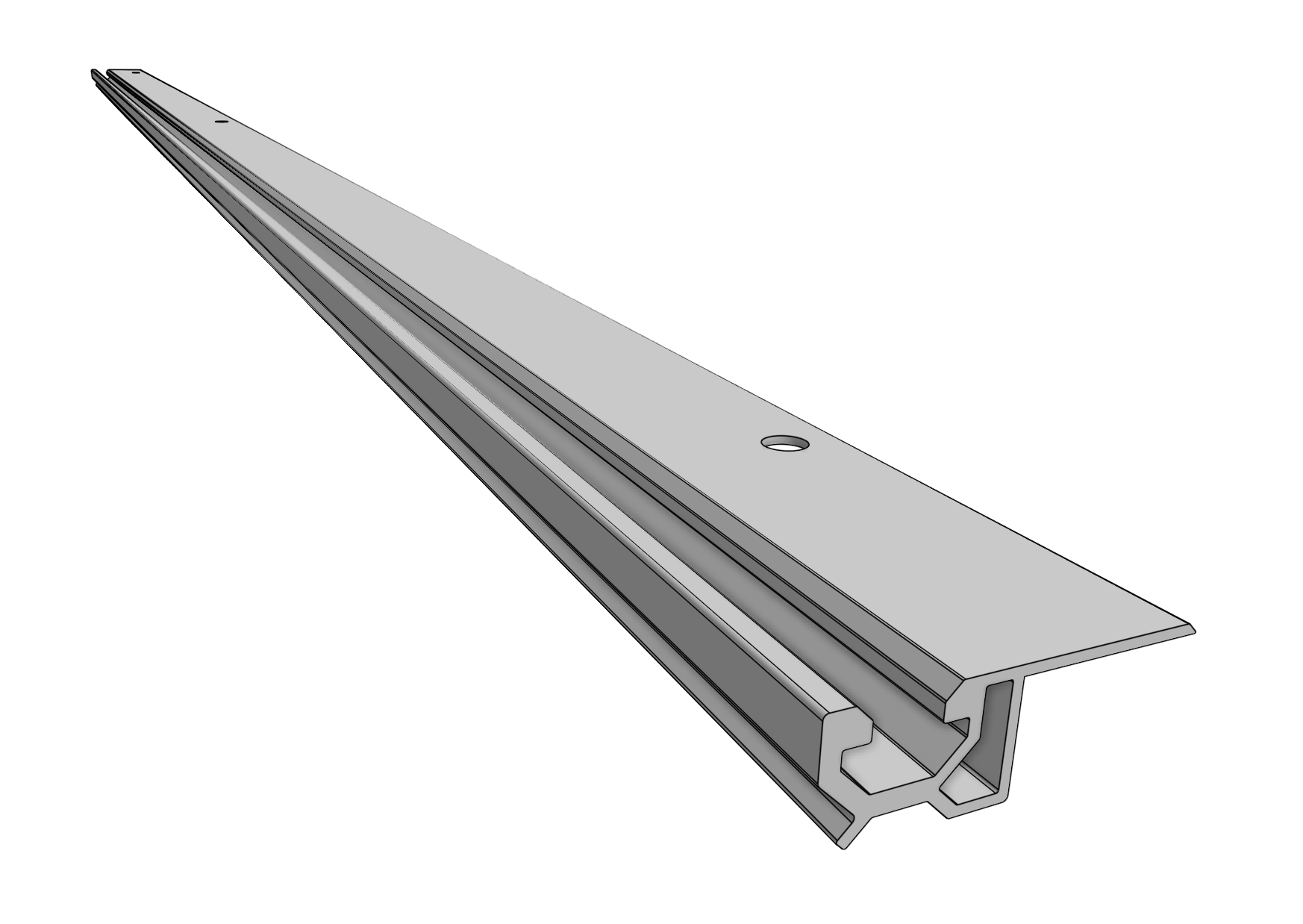

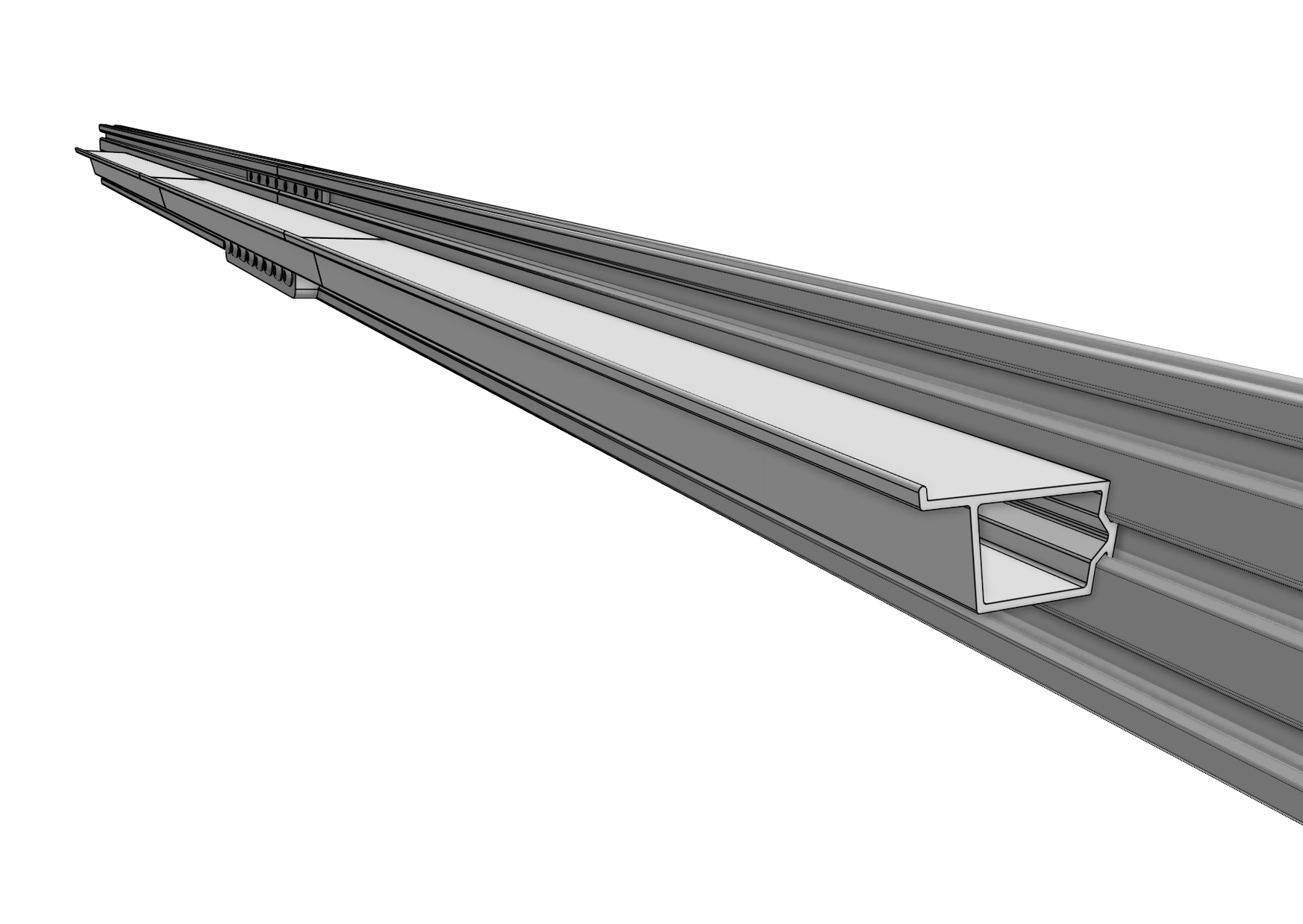

Track extrusions

Building on the success of the simplified track design introduced in v1.7, the v1.8 track extrusions are now even lighter, more compact, and easier to assemble. Coming in 1m lengths, the new tracks are co-packaged with the rest of the FarmBot kit, further saving cost and shipping weight. Meanwhile, they are now joined together with a nut bar in the upper slot, making it easier to access the setscrews during installation and maintenance.

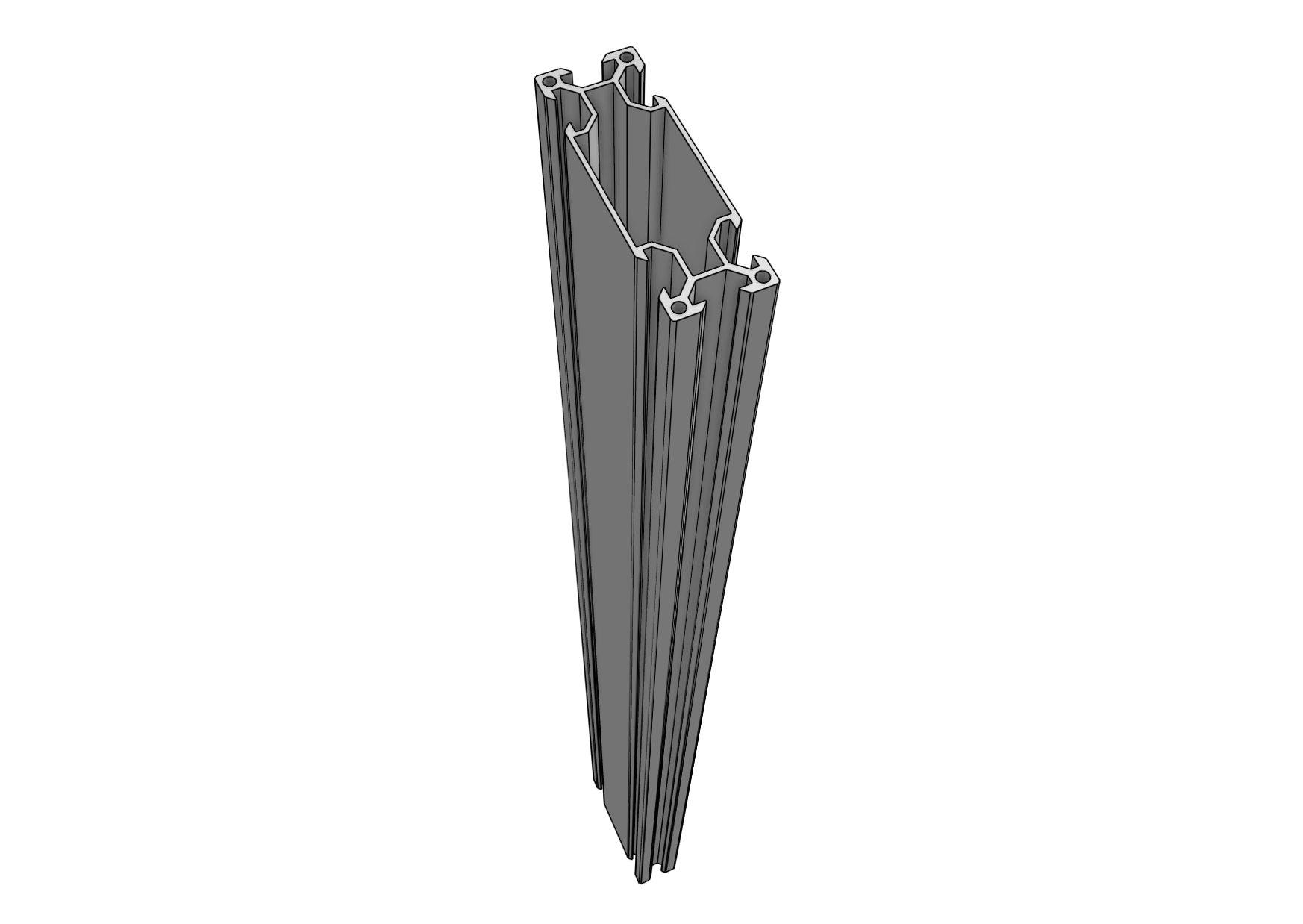

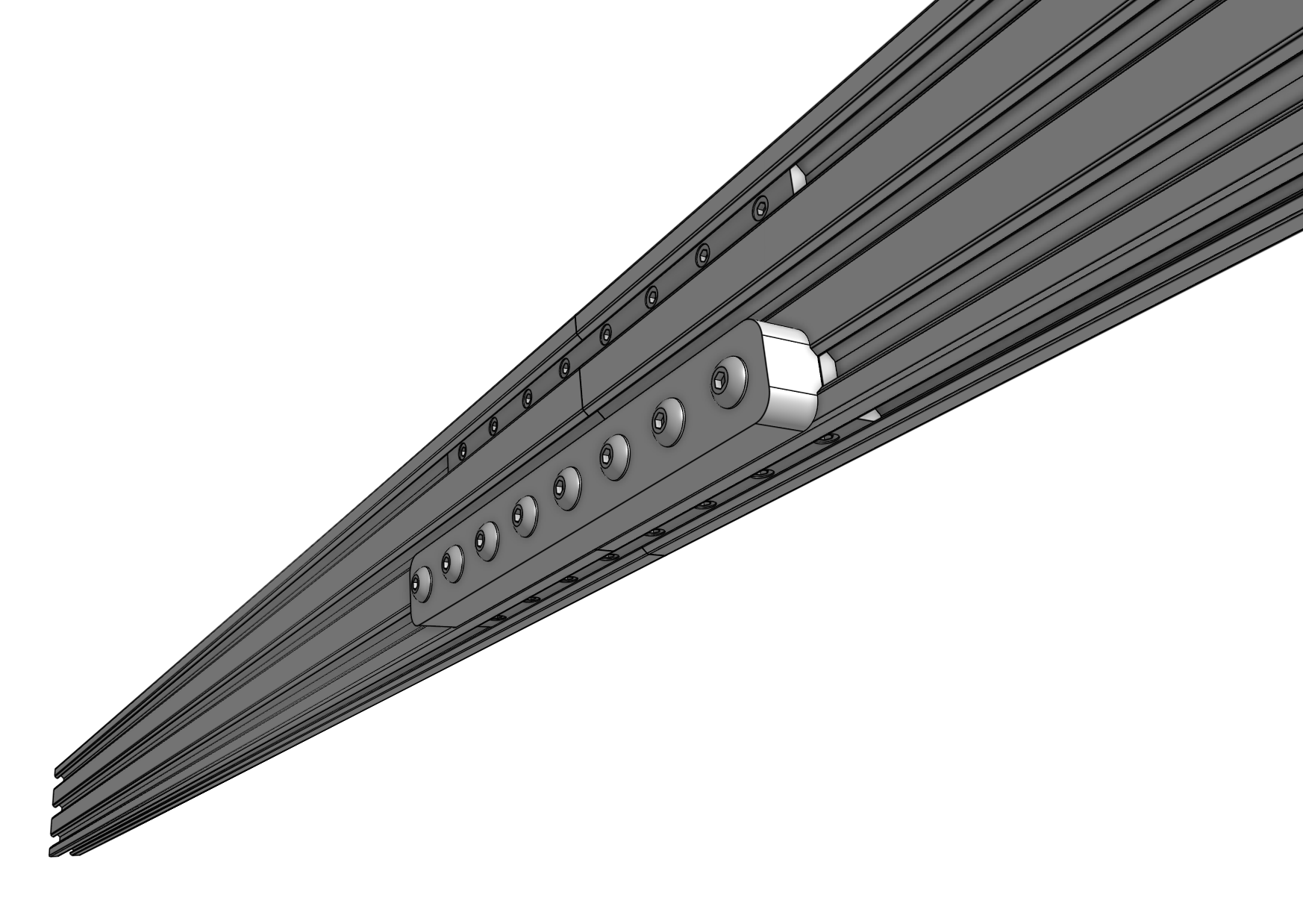

Gantry columns

Also building upon v1.7, the new v1.8 gantry column profiles are now lighter weight, further improving incremental machine performance and contributing to overall weight savings.

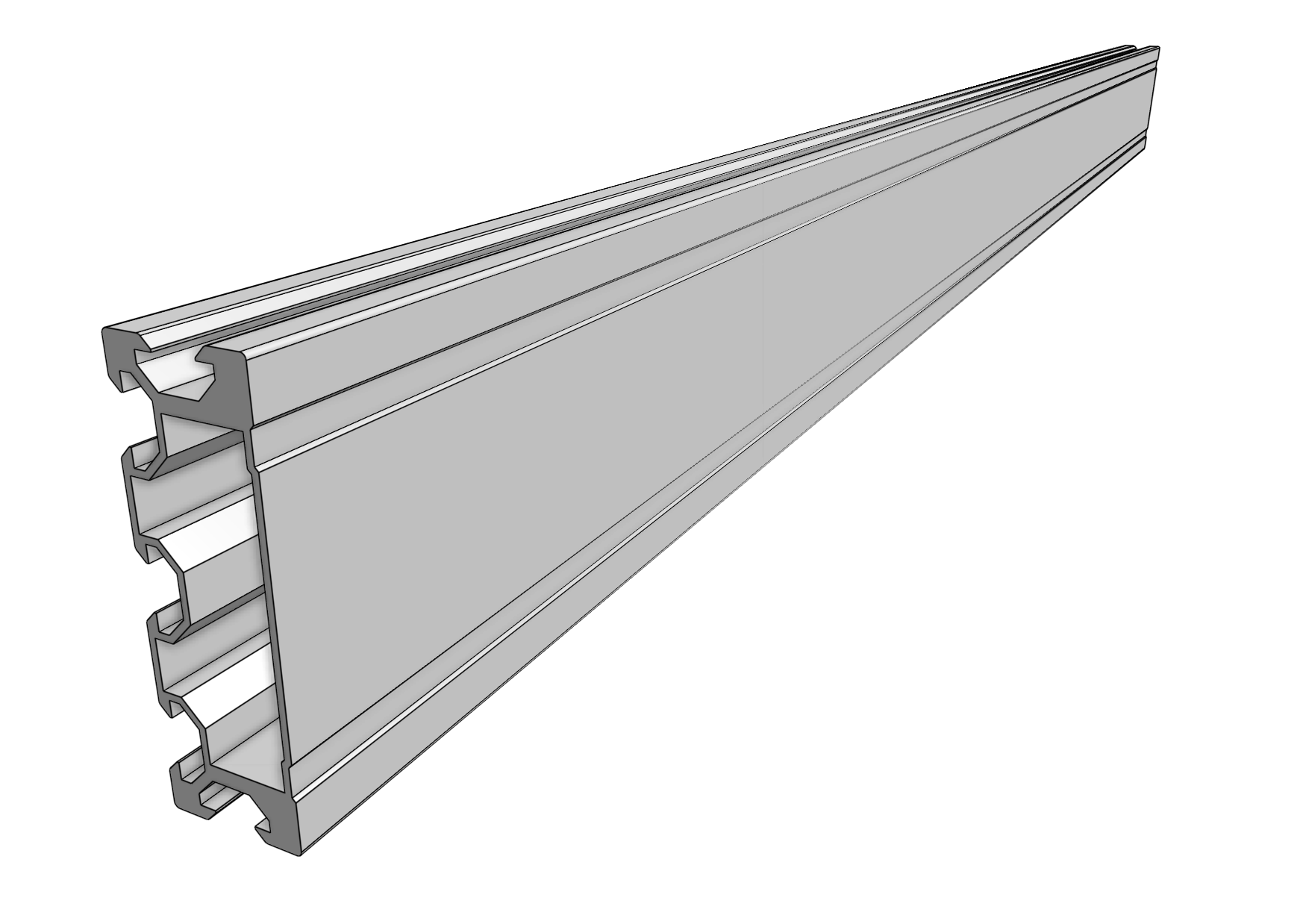

Gantry main beam

New gantry main beams are now significantly lighter weight without compromising on strength, while offering a refined aesthetic on the front face. The new beams are also now shorter and more numerous (two 0.75m beams for Genesis and three 1m beams for Genesis XL) in order to be co-packaged with the rest of the FarmBot kit.

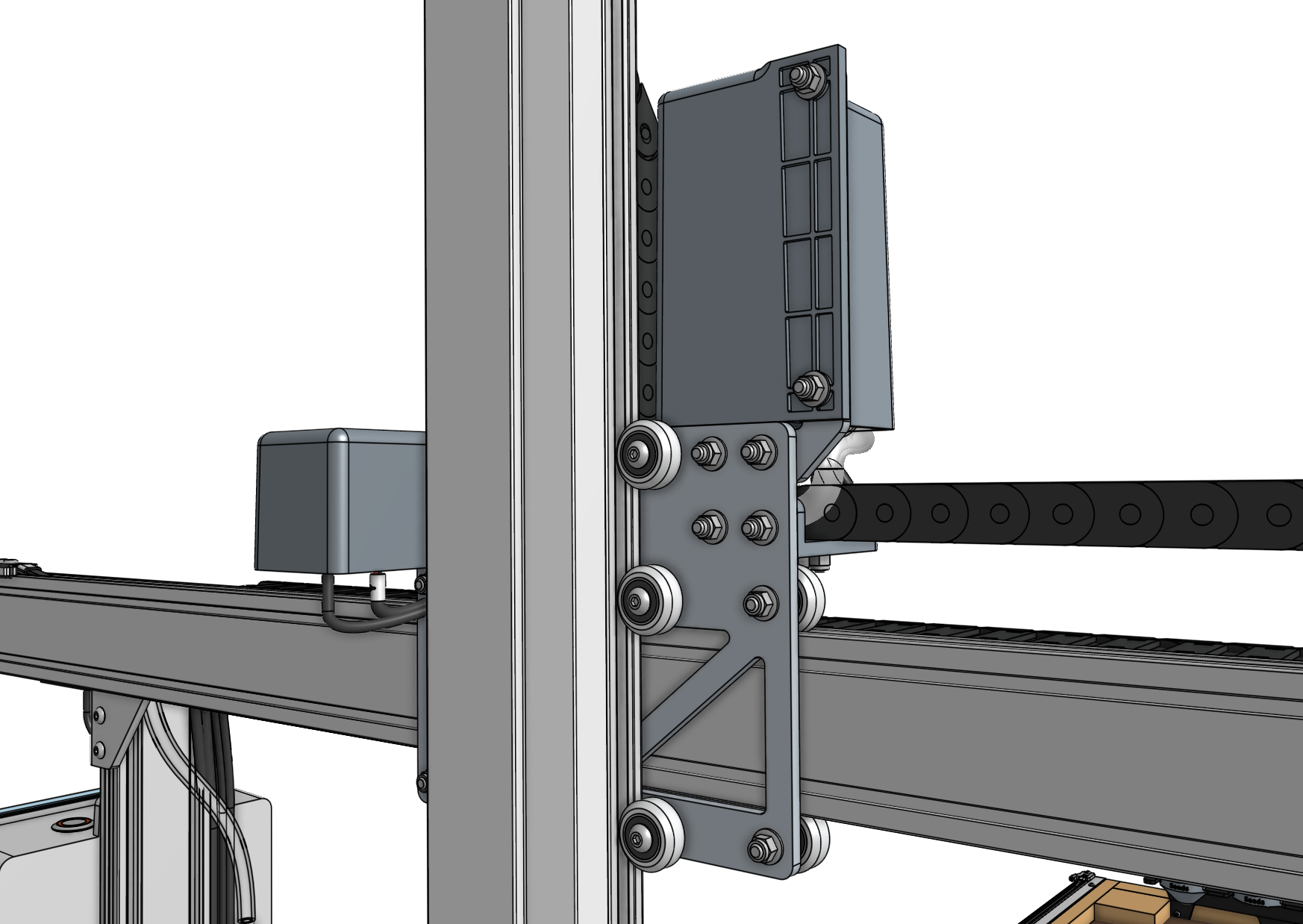

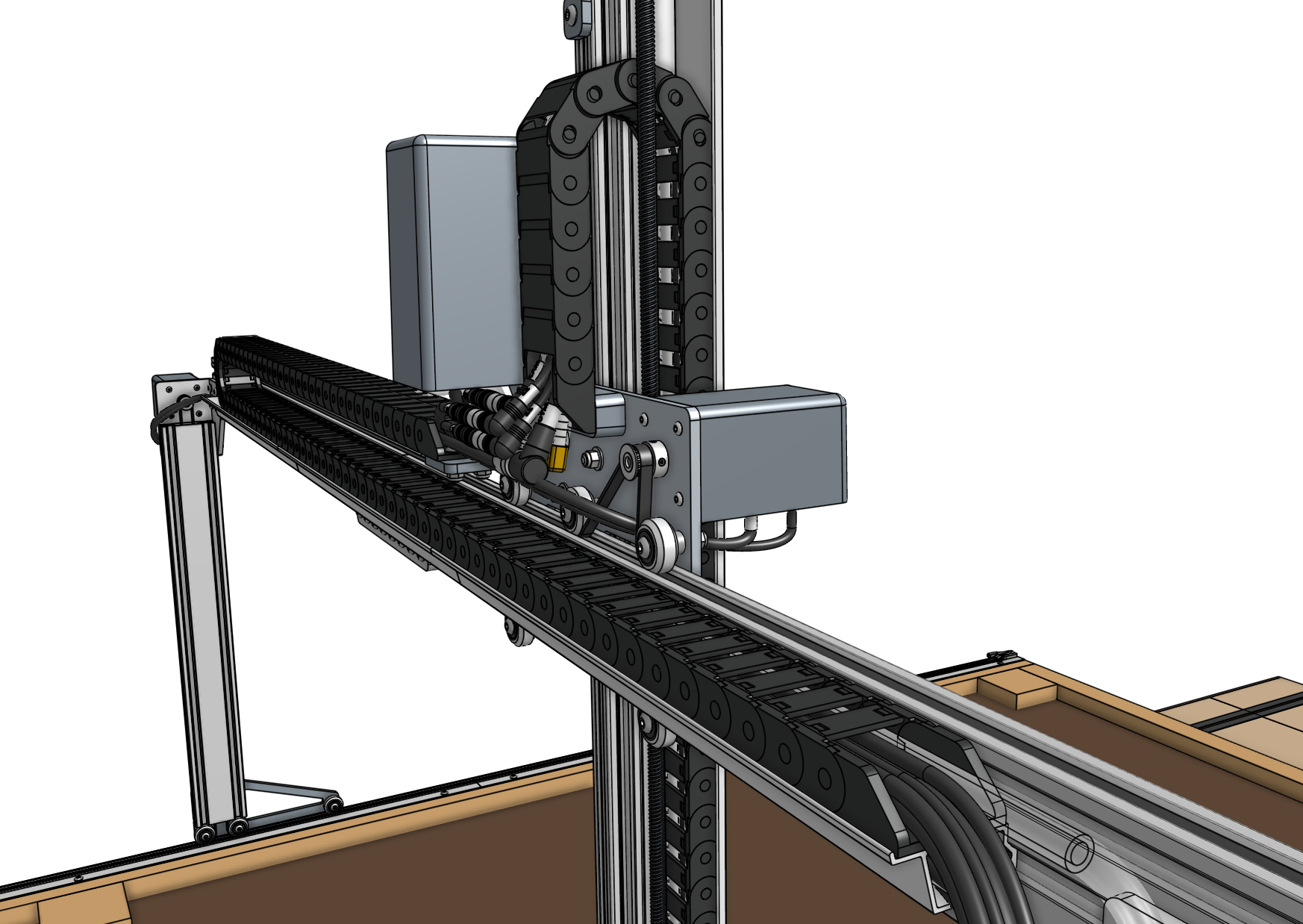

Extruded cable carrier supports

New extruded horizontal cable carrier supports and vertical cable carrier supports are designed to slide into the gantry main beam and z-axis extrusion slots. They are lower cost, easier and faster to assemble, reduce total part count, better support and conceal the cables routed through them, and create a diffused look for the LED strip.

Gantry joining bar

A new gantry joining bar has been introduced to connect the gantry main beams together while being compatible with the new cable carrier supports. Combined with new 160mm nut bars, the main beam assembly retains its needed rigidity and strength.

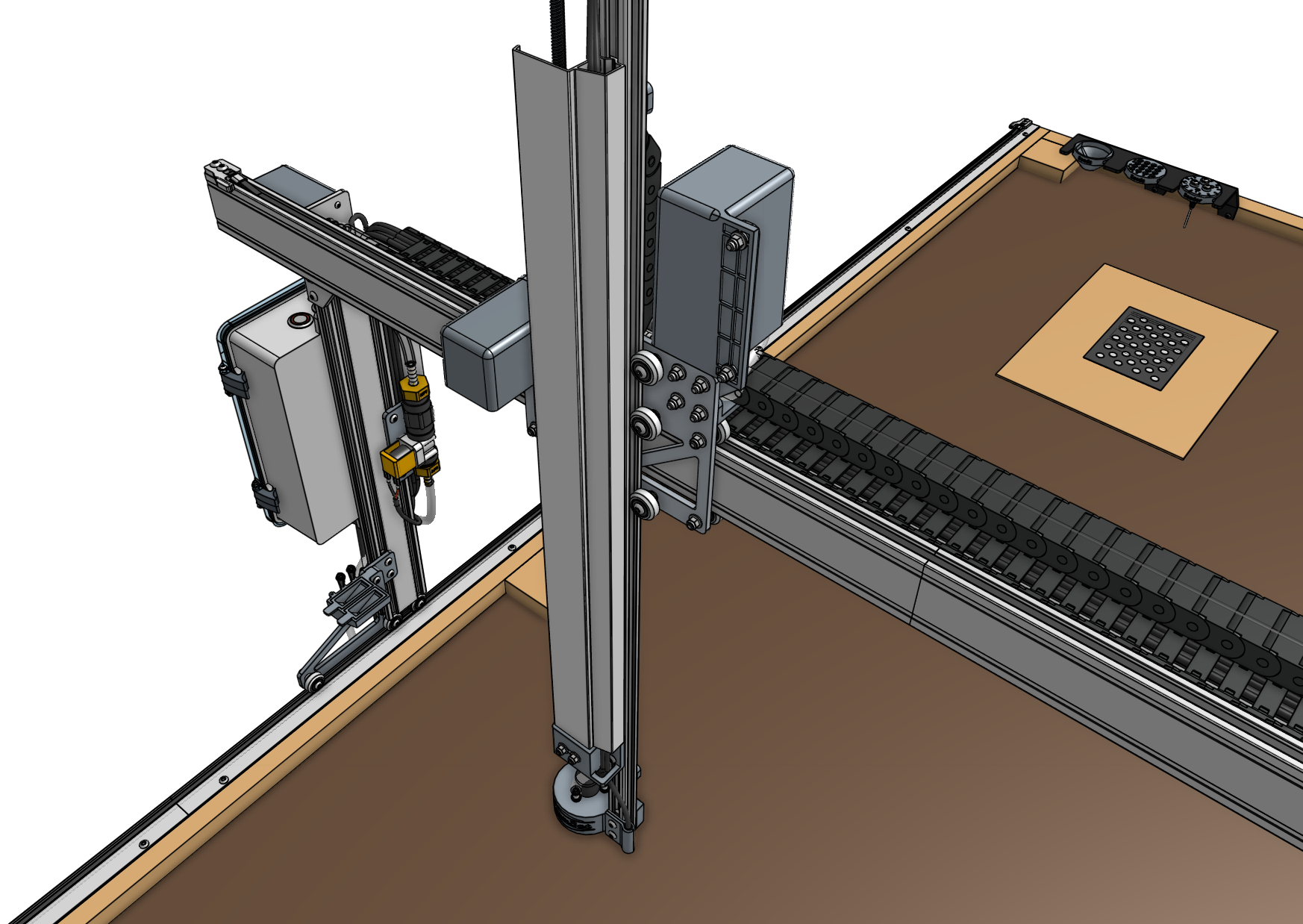

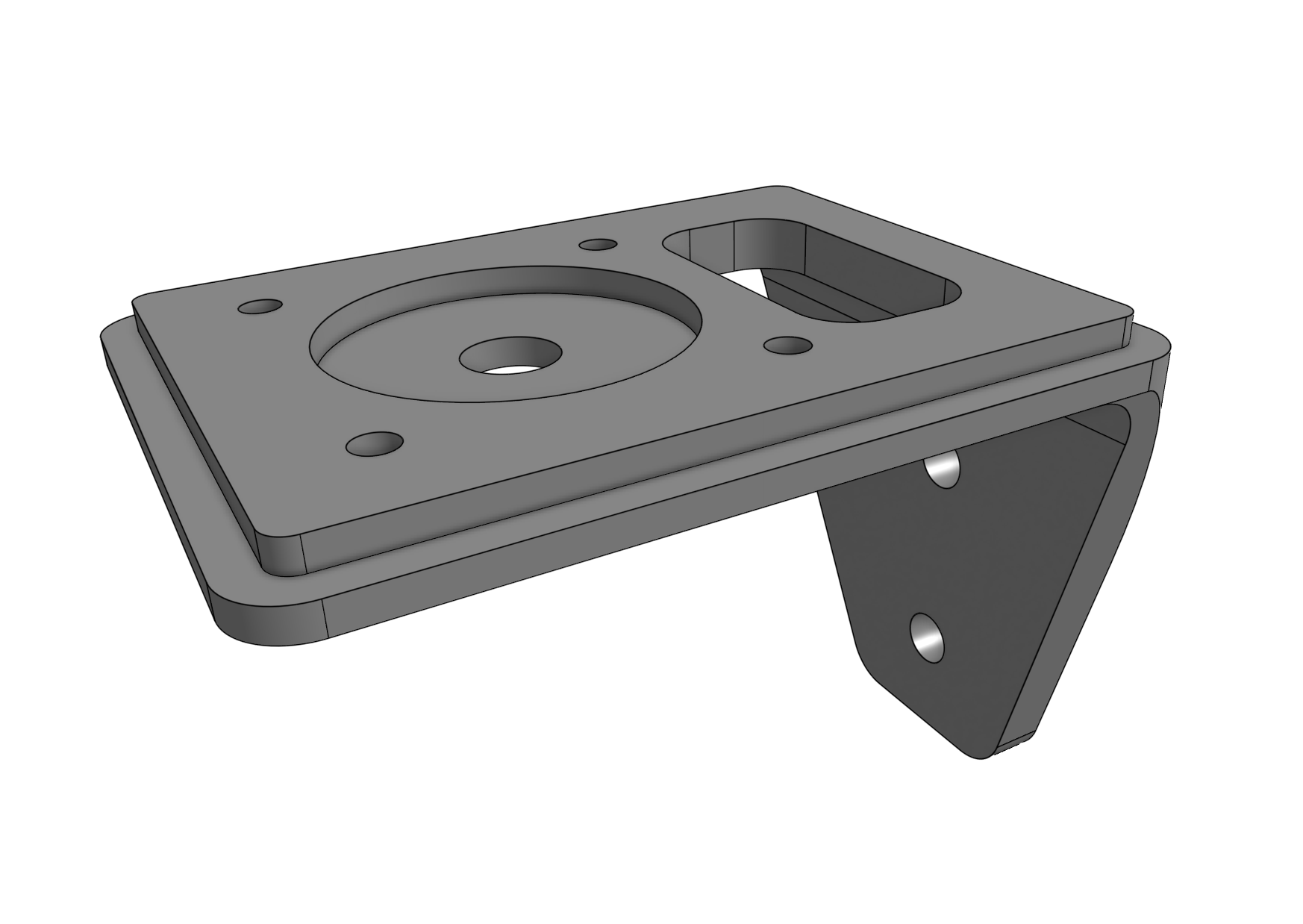

Relocated vacuum pump

The vacuum pump has been relocated to the cross-slide, reducing the weight and size of the Z-axis to improve movements. This change also resulted in the need for a new vacuum pump mount as well as the elimination of the Z-axis vacuum cable and a revision to the Y vacuum pump cable.

Smaller Y and Z cable carriers

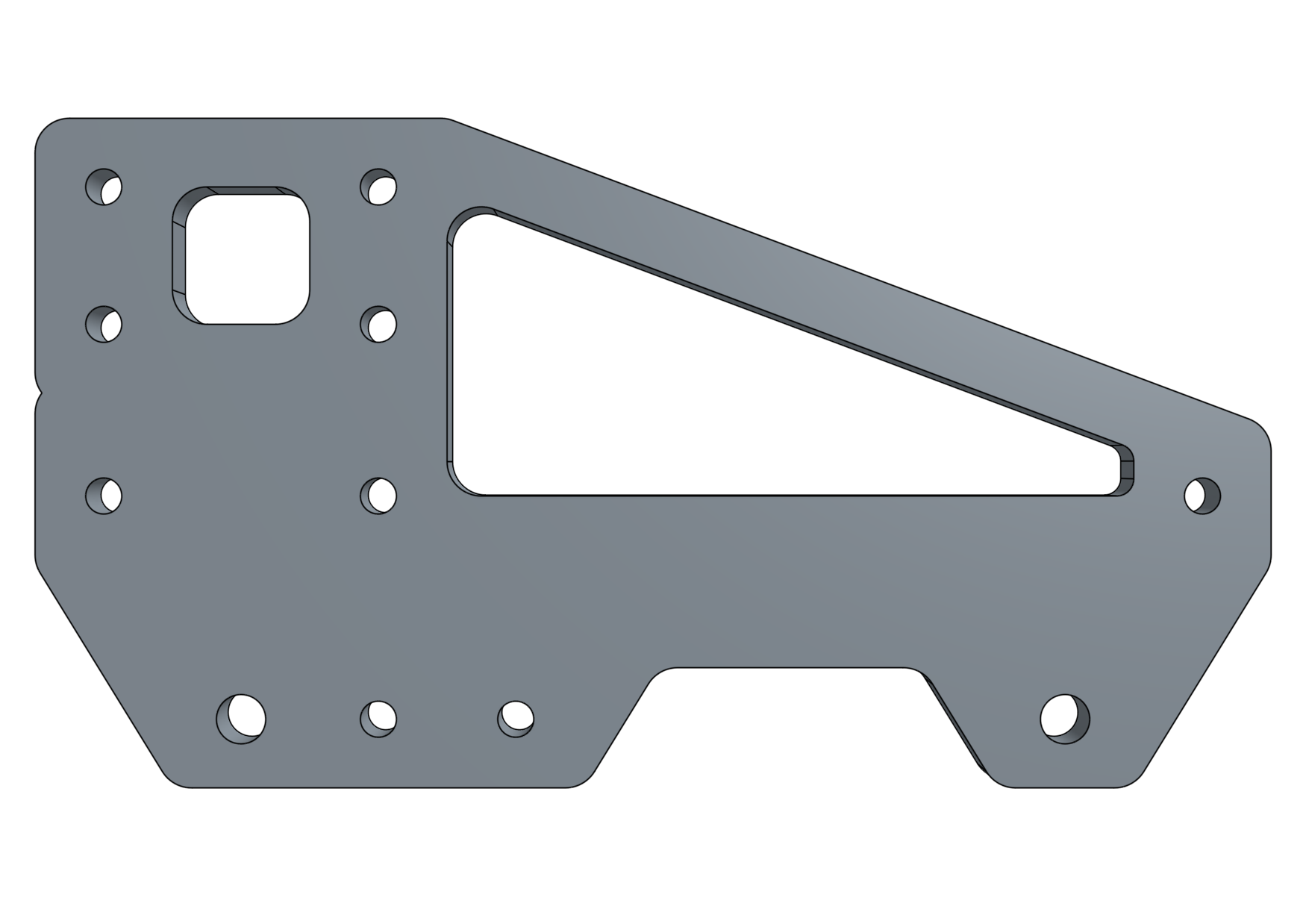

The Y and Z cable carriers are now 20mm narrower (15x30 internal size), incrementally improving movements, costs, and shipping weight. These changes also required a new cross-slide plate, vertical motor housing, 40mm cable carrier spacer block, 60mm cable carrier mount, and 40mm vertical cable carrier support.

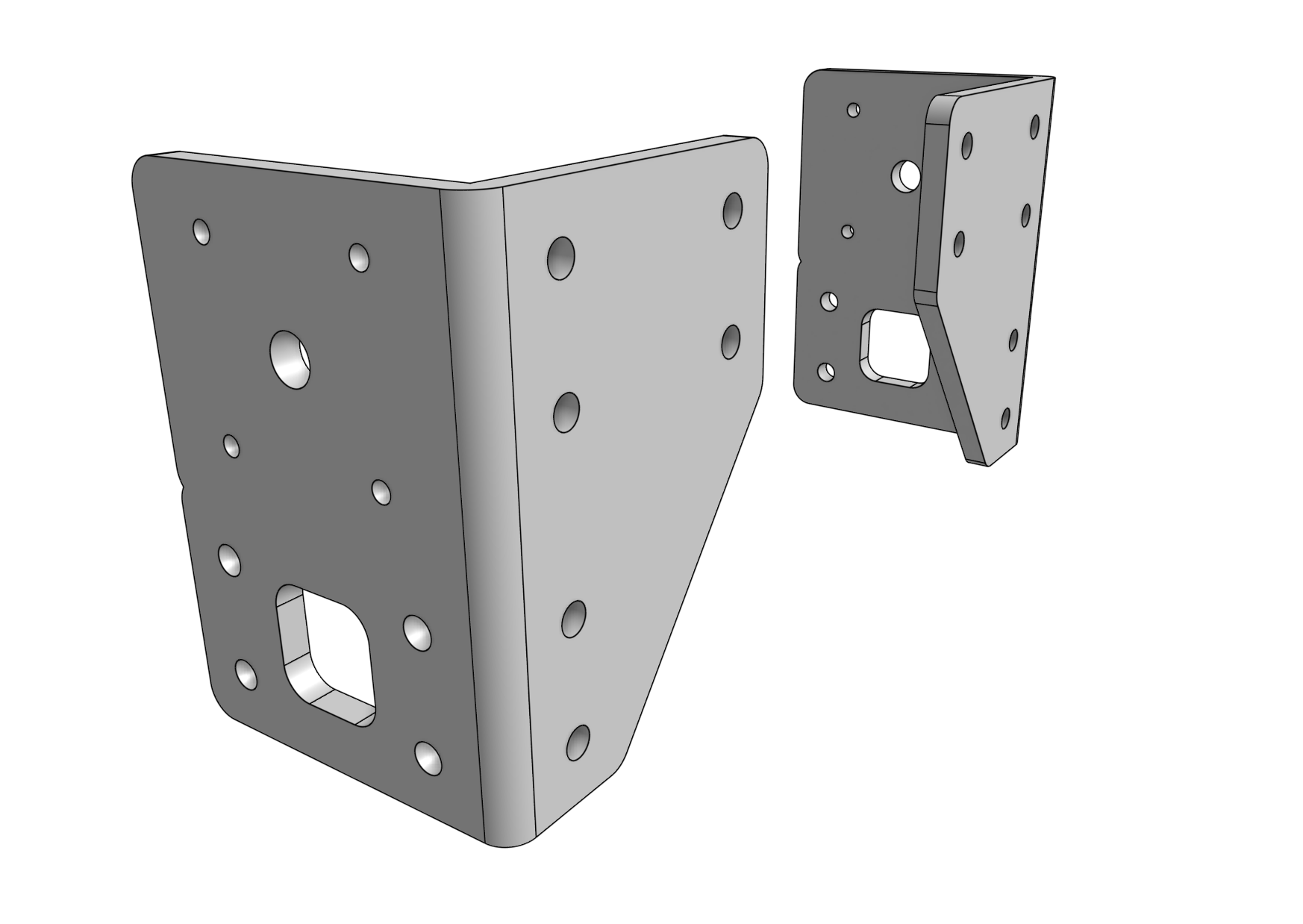

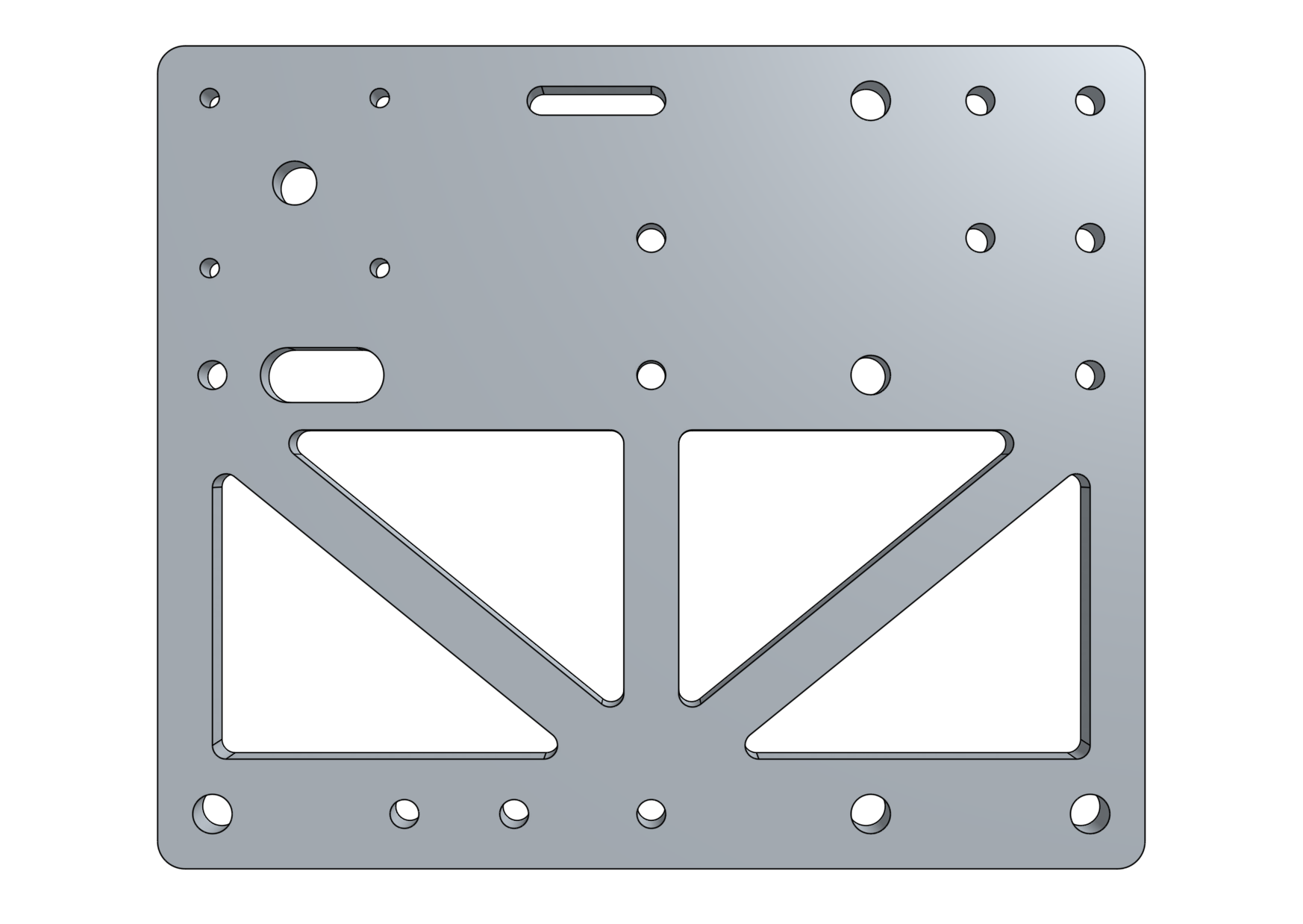

Lighter plates and brackets

The gantry wheel plates, gantry corner brackets, cross-slide plate, and z-axis motor mount have all been optimized to be lighter weight and use smaller 40mm nut bars instead of 60mm nut bars for assembly onto extrusions.

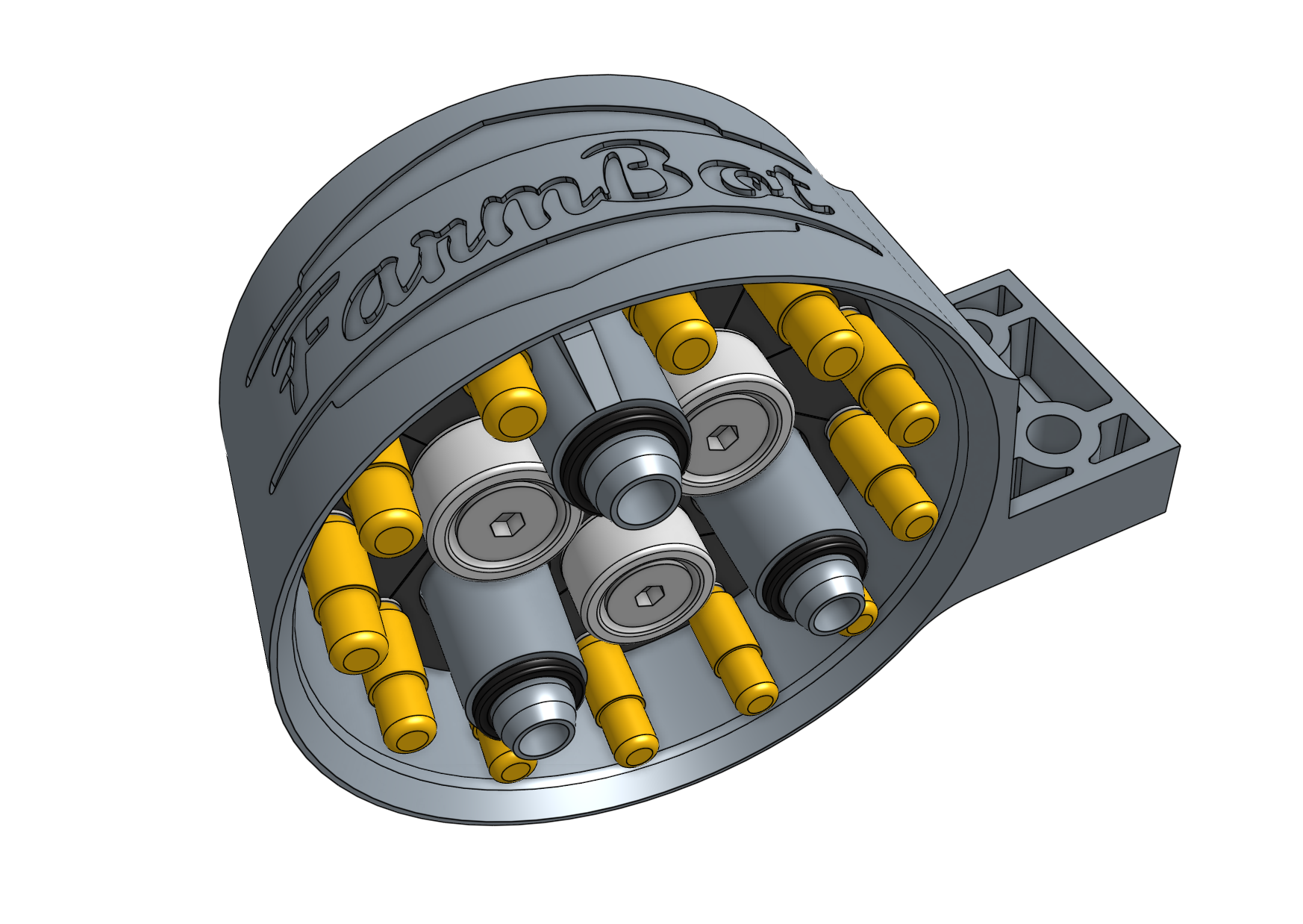

Countersunk UTM magnets

The UTM now uses stronger countersunk magnets to more securely hold all tools in place. Meanwhile, the rotary tool now uses standard magnets like the other three tools.

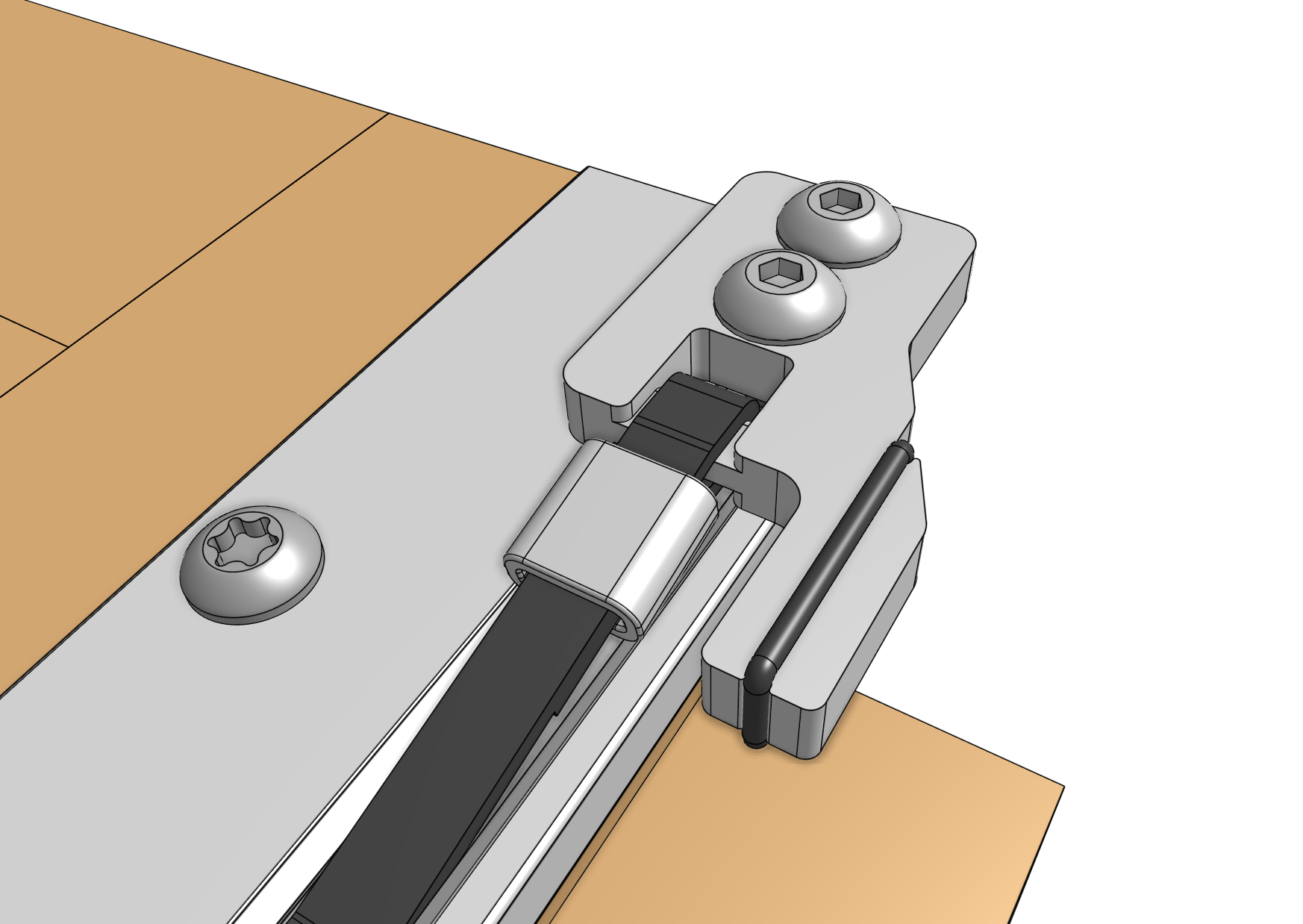

Belt clip dampeners

The belt clips now feature small divots to hold a rubber o-ring belt clip dampener to reduce noise from homing and automatic calibration procedures.

Spare parts resupply

In addition to shipping out many new full kits, we have now fulfilled all outstanding orders for spare and replacement parts that were previously on hold due to a lack of inventory.

We have also made these new parts available on our online shop. Some common items include belt in 4.5m and 7.5m lengths, v1.7 Farmduinos (same as what is included in v1.8 machines and some later production v1.6 machines), fully pre-assembled v1.7 electronics boxes, nut bars, and cameras.

New documentation

And of course, as part of our commitment to producing 100% open-source hardware, you’ll now find updated documentation detailing not only the step-by-step assembly instructions, but also the change log, full bill of materials, CAD models, and more. Enjoy!