Why does farm bot move noticeably faster down then up?

I can not find a seperate speed for each direction

The short answer is that the axis should move at the same speed no matter what direction the Farmbot is moving it in.

With the Z axis, however, there is some gravity at play in the downwards movement, so the motor finds it easier to overcome any mechanical friction in that direction. This could lead to a percieved faster motion when the axis is travelling downwards. The critical thing however, is the distance travelled. As long as the commanded distance for the axis to travel is the same in both directions, there is nothing to worry about.

@chrisb agree with @dmbgo and add that it’s well worth reducing friction in the Z-screw vertical axis.

You can find many useful posts in this forum about suitable lubricants.

(aside : your question also begs more detail of the Z stepper driver + Encoder processing in the Farmduino firmware . .  . . I’ll try to dig this out. I’m assuming that higher upward friction slows the actual Z-motor step duration and the Encoder simply reflects that)

. . I’ll try to dig this out. I’m assuming that higher upward friction slows the actual Z-motor step duration and the Encoder simply reflects that)

I have disconnected the lead screw so there is no load and the speed is different.

The speed difference is noticeable not perceived, it also times out going up 500mm but not down

@chrisb is that with motor and leadscrew disconnected ?

What is your setting ERROR HANDLING \ TIMEOUT AFTER (SECONDS) for Z axis ?

If that setting is 120s then the issue is looking more like hardware to me ( motor+encoder, stepper driver, etc )

@chrisb

Did you notice this input field in the motors setting page? Unfortunately I can’t test it as my device is still in winter mode. Afaik you can use different speeds and accelerations for each direction.

I thought that was for the homing speed, not a different direction speed setting

I’ll check it out

yeah, that was it

“I thought that was for the homing speed, not a different direction speed setting

I’ll check it out

yeah, that was it”

FYI, I also thought that setting was only used during homing, and that it used the other " Max speed" setting for the axis at other times - in both directions. Some more definitive wording of the description of the function may be appropriate.

Please check these items to get your Z-Axis working at the same speed up and down:

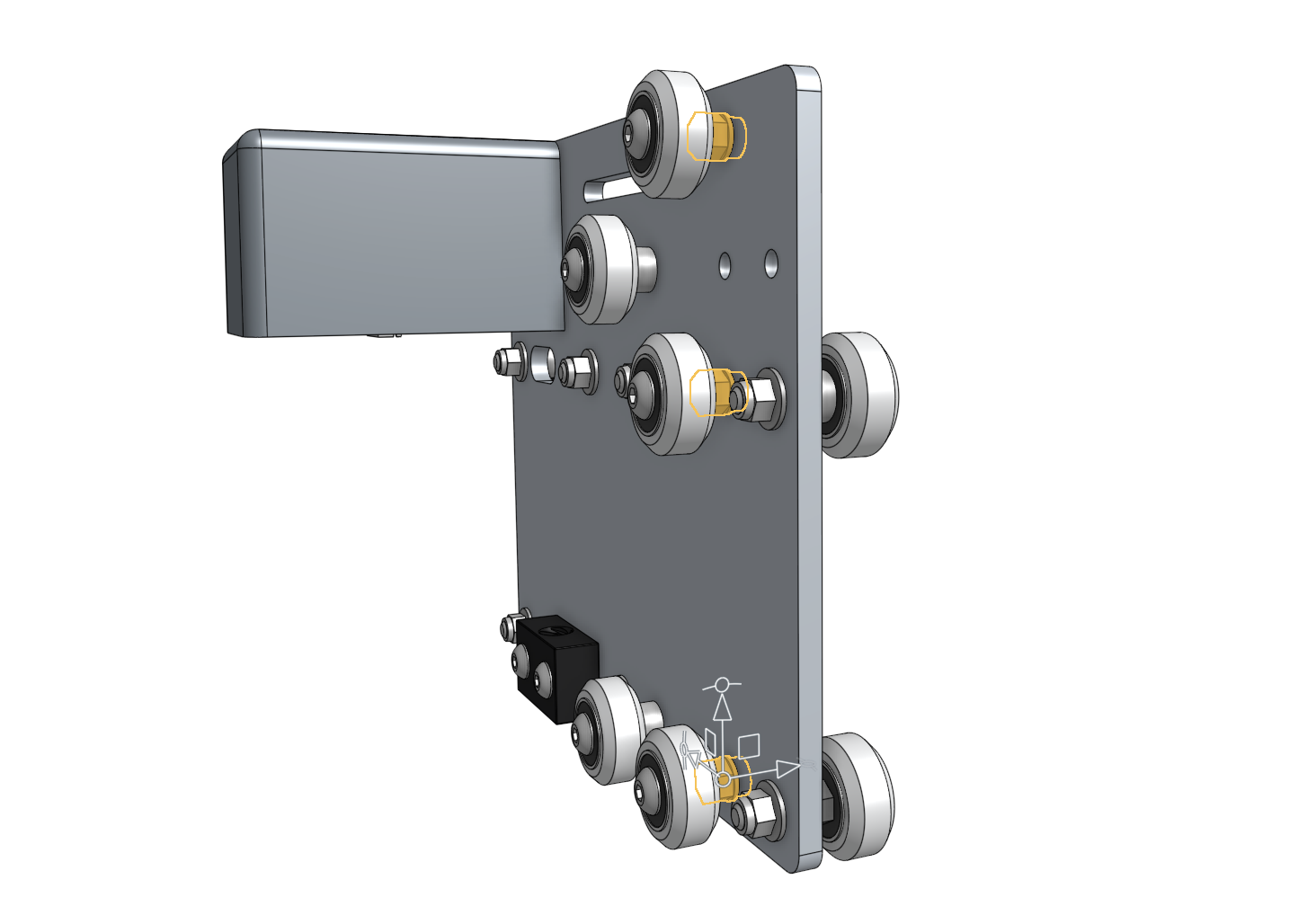

The exact component you need to check is the motor to screw shaft coupling. Tighten the coupling’s lower and upper set screws with the 2.5mm hex key. Use the hex key to tighten up the Z-Axis lead screw to the motor coupling component and make sure that there is no slip on the leadscrew.

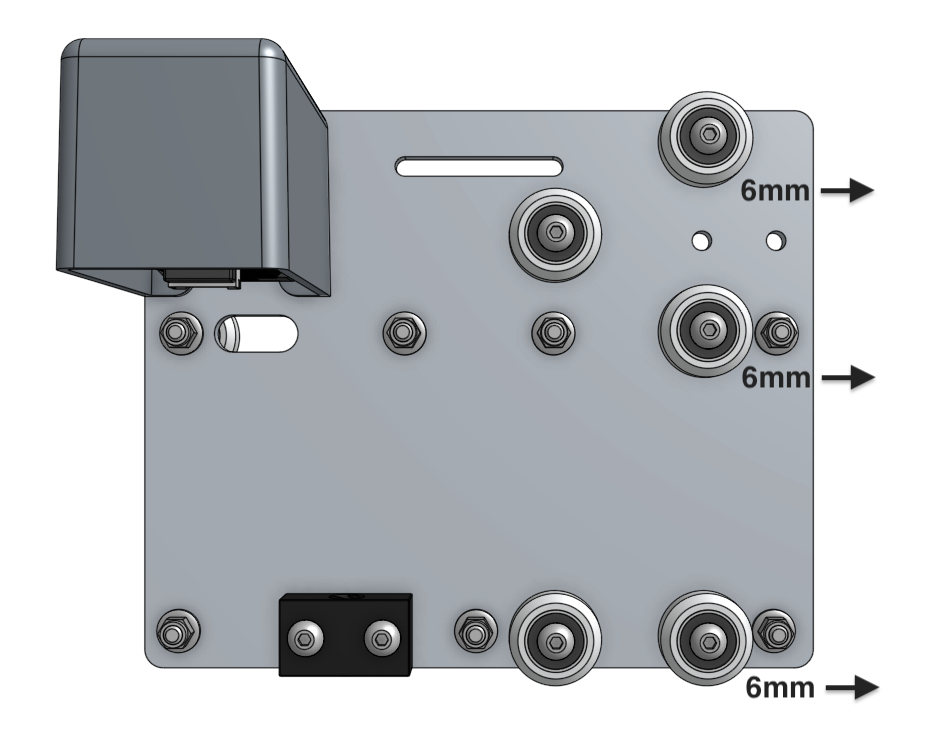

2.Check the eccentric spacers. Check the eccentric spacers and make sure that the 6mm markings on the eccentric spacers are facing away to the motor. You can reduce the resistance to movement by orienting the eccentric spacers away from the leadscrew and motor. This will reduce the bite force that the wheels have on the Z-Axis. I have seen FarmBots where the Z-Axis has so little resistance to movement, with the motors unpowered, a user can lift the entire Z-Axis with the upward force of an index finger. The leadscrew turns and the entire Z-Axis is lifted, and it is really remarkable.

Once you have checked those two items, please review this troubleshooting page:

One of the main reasons for motor stalls on the Z-Axis is small resistances in the movement of the Z-Axis lead screw as it slides through the lead screw block. To reduce or eliminate these resistances to movement, you can use dry graphite lubricant spray on the entire surface of the leadscrew. This dry non-oil based lubricant spray will coat the surface with a fast drying coating of graphite which will create a slippery surface and significantly reduce the resistance of movement through the lead screw block and it will also decrease the noise level of the leadscrew.

We have found a product called Jig-a-Loo Graphite Lubricant and we suggest that you use this to significantly reduce friction on the FarmBot Z-Axis lead screw .

You should apply enough graphite lubricant so that the hue of the screw should look significantly darker than the original silver metallic color. You should use enough graphite lubricant so that the screw should appear black or dark grey. This will allow the screw to operate without friction and vibrations. [We NEVER recommend using an oil, silicon, or lithium based lubricant because in the garden it will attract dust and gum up causing even more problems in the future. Only graphite lubricants are acceptable]

Here is a YouTube video that shows how the product is used and the typical applications. It is a perfect product to use on the lead screw.

The issue has been resolved

What was the major action you took to resolve the issue in your case?

See the post by Ascend

The wording of the configuration field “Max Speed Toward Home” is a bit misleading

Z-axis does have different speeds in each direction

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.