When I ask to go down… no problem. When I ask to go back up, It makes a high pitch noise and goes down. If I help it. it goes up. Axis is moving freely, talked with support from FarmBot, they thought it was the farmduino… they sent a new one + a Z axis stepper motor just in case but they were pretty sure that the farmduino was the problem. We changed the board, and it’s doing the same thing! It looks like the Stepper is not strong enough to lift the Express V1.1. Help!

The main reason for motor stalls on the Z-Axis is small mechanical resistances in the movement of the Z-Axis lead screw.

So you need to take steps to reduce the resistance to movement. On low resistance Farmbots, it is possible to have so little resistance to movement on the Z-Axis that if the Z-Axis motor is turned off, the user can push up on the Z-Axis aluminum extrusion and the leadscrew will spin around as the whole Z-Axis assembly moves upwards in response to the push.

Eccentric Spacers - Adjust the bite force on the Z-Axis Aluminum Extrusion

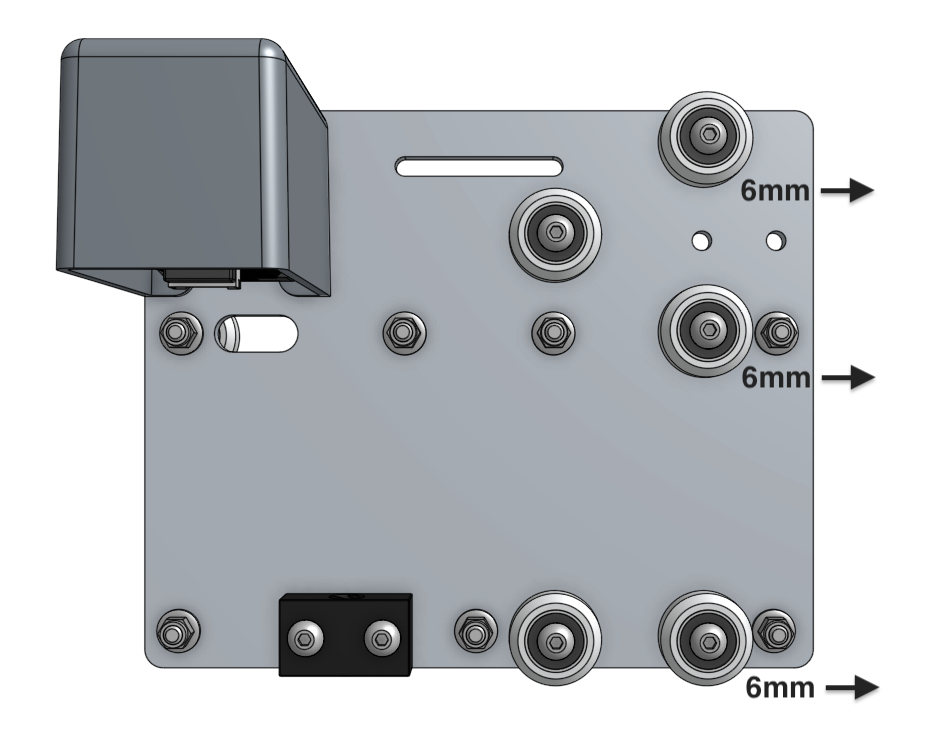

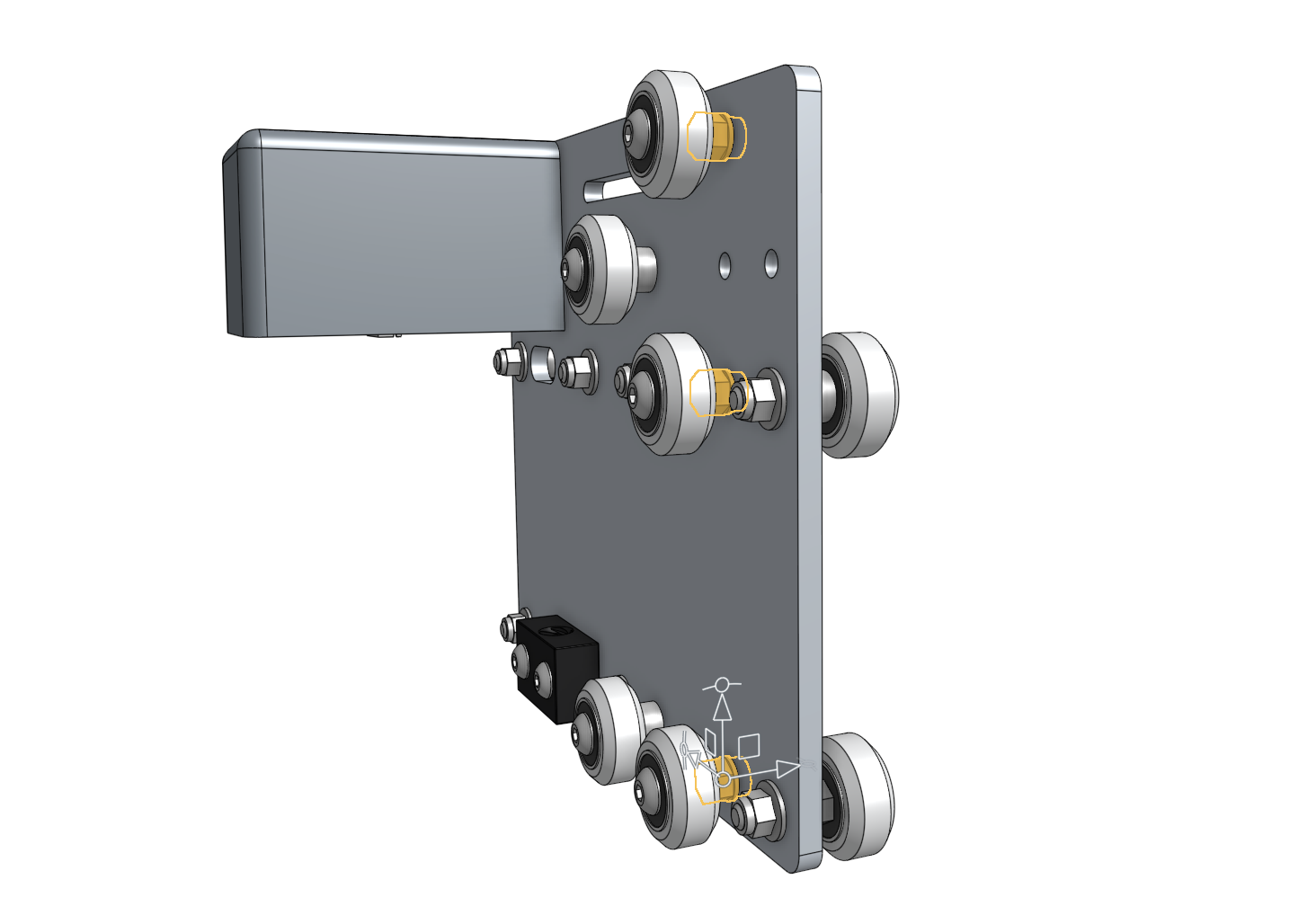

The eccentric spacers have the notation 6mm on one of the flat sides.

You need to adjust your eccentric spacers to reduce the bite force of the wheels on the Z-Axis Aluminum Extrusion. Take a small wrench and turn the eccentric spacers so that the 6mm mark is facing directly away from the Y-Axis motor. On the diagram below you will see the 6mm markings facing directly to the right.

Z-Axis Eccentric Spacers

Add the dry graphite lubricant to the leadscrew

The main reason for motor stalls on the Z-Axis is small resistances in the movement of the Z-Axis lead screw as it slides through the lead screw block. To reduce or eliminate these resistances to movement, you can use dry graphite lubricant spray on the entire surface of the leadscrew. This dry non-oil based lubricant spray will coat the surface with a fast drying coating of graphite which will create a slippery surface and significantly reduce the resistance of movement through the lead screw block and it will also decrease the noise level of the leadscrew.

We have found a product called Jig-a-Loo Graphite Lubricant and we suggest that you use this to significantly reduce friction on the FarmBot Z-Axis lead screw.

You should apply enough graphite lubricant so that the hue of the screw should look significantly darker than the original silver metallic color. You should use enough graphite lubricant so that the screw should appear black or dark grey. This will allow the screw to operate without friction and vibrations. [We NEVER recommend using an oil, silicon, or lithium based lubricant because in the garden it will attract dust and gum up causing even more problems in the future. Only graphite lubricants are acceptable]

Here is a YouTube video that shows how the product is used and the typical applications. It is a perfect product to use on the lead screw.

If you can’t find Graphite Extreme there is also similar lubricants ZEP Dry-Film Graphite Lubricant, ABUS PS 88 - Spray Gleitmittel (Germany Graphit Schmiermittel Spray)

These products will also likely work just as well and in North America they are available at Home Depot, Lowes, Wal-Mart and Canadian Tire in North America and at specialty hardware and automotive supply shops around the world and on Amazon.

https://www.amazon.com/JIG-A-LOO-10-9oz-Multi-Graphite-Lubricant/dp/B08285N7LG/

Please apply the graphite lubricant to the bottom 90% of the lead screw leaving the very top 10% unlubricated so that a sturdy grip can be applied to leadscrew by the coupler.

If these mechanical adjustments are not effective, you may want to increase the motor current to your Z-Axis motor.

Please email us at CONTACT@FARM.BOT for more troubleshooting support.

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.