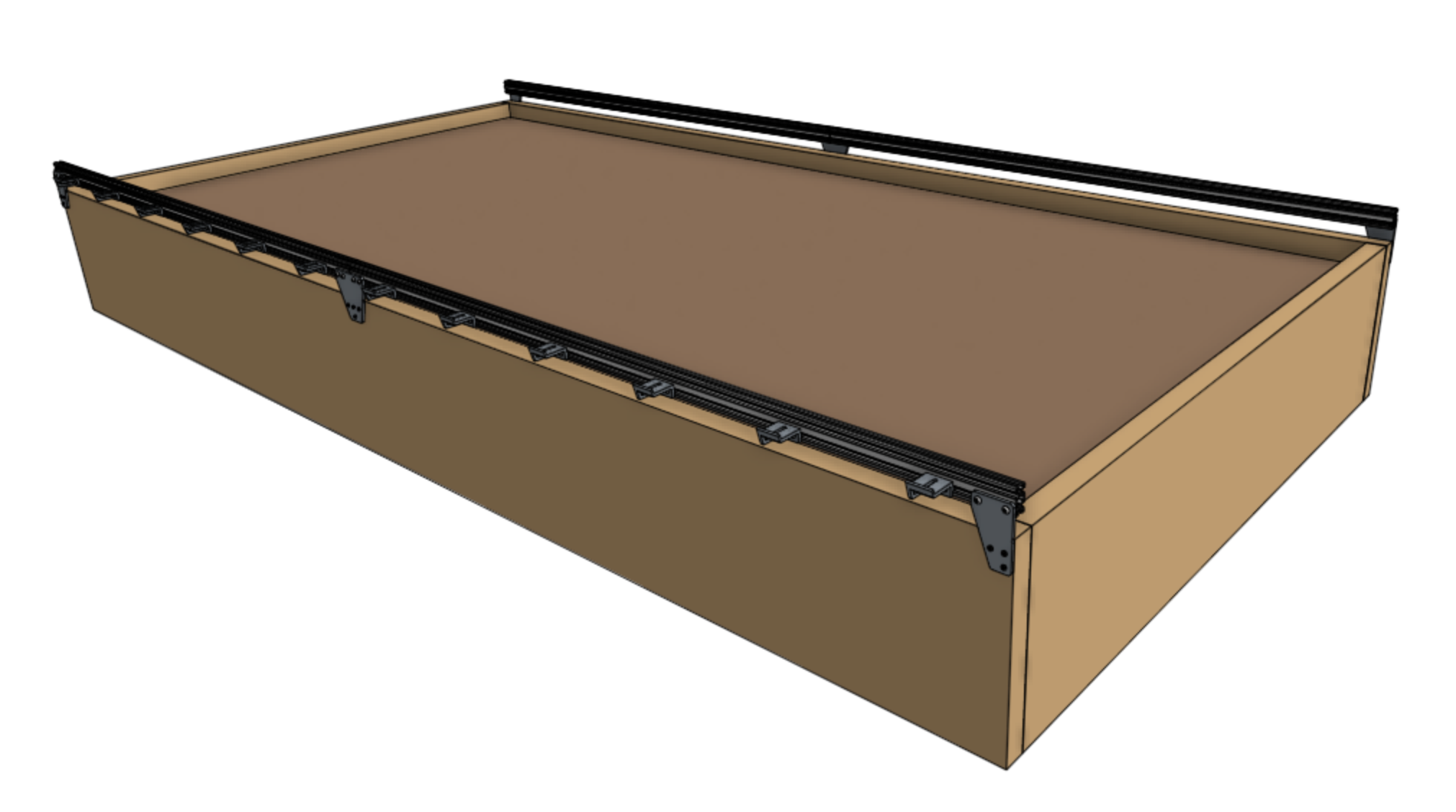

HI everyone, last year I built my raised bed and farmbot XL but have had ongoing battles getting the rails to remain parallel. As a result the gantry regularly stalls and I am in despair, having spent many many many man-hours adjusting over and over only to find it failing again even though the distance changes are maybe just a couple of mm. Below is a picture of the raised bed taken from the inside before we filled it with soil. You’ll see we built the raised bed using two layers of heavy oak beams. My suspicion is that despite their weight these move a tiny bit as temperature and moisture levels change and perhaps that’s what’s causing the issue. Starting from scratch though is not attractive so I’m wondering if the community has any experience of similar problems and suggestions, Thanks

@piltdowndave Have you tried:

- increasing the

motor current - Increasing

maxed missed steps - Lightly sanding the junction of certain tracks- not too much though, since this can damage the rails.

Also, is it safe to assume the issues are happening mostly on the X axis?

In addition to @RickCarlino’s excellent suggestions, you can also try loosening the wheels a little bit. It can make a world of difference.

Other things that worked for me: Stall on X-Axis / Leak / Farmbot not responding

Finally and if all else fails, you can remove some non-essential wheels (more info here:Genesis XL 1.5 / Reduce stall detection sensitivity) :

I can’t think of any reason the lateral movement of the wheels couldn’t be increased quite a bit if necessary. The main restricting factor is the length of the bolts holding the wheels on to the gantry, these could be replaced with longer bolts, if necessary. A wheel that is set up to “float” laterally would allow the wheel to cope with quite a bit of rail displacement due to movement of the substructure. The main function of the wheels is to use their V shape to prevent the gantry from becoming detached from the rails, so past a certain limit, vertical movement would possibly cause issues.

Regards

David Maher

Thank you @RickCarlino @ClosedCircuit @dmbgo … yes this is an X-Axis only problem.

There are a couple of things suggested that I haven’t tried yet, the idea of allowing more lateral movement using longer bolts is particularly interesting as this might best adapt to ongoing substructure movement. Further suggestions welcome just in case I need more ammo. All the best

@piltdowndave Dave,

Would you be able to send us a YouTube video of the movement of your FarmBot? If you can upload a video to YoutTube and post the link here we can view it and we can likely make suggestions and corrections to get you on your way.

I just wanted to mention that the construction of the X-Axis tracks is the most important part of the whole assembly process. Please spend extra time to plan out this stage of the construction. Take time and understand the instructions fully prior to starting the work. Ideally the fixed raised bed need to be constructed upon a sturdy supporting structure.

We suggest that a composite wood product, or a cedar, redwood, cypress and other naturally rot-resistant woods are likely the best materials to use for the supporting infrastructure. If you do decide to go with pressure treated wood, please ensure that there is a plastic or rubber moisture barrier between your soil and the pressure treated wood to protect against chemical leaching into the soil.

The X-Axis tracks need to be level and as perfectly parallel as possible. Please ensure that the X-Axis tracks are aligned and as precisely constructed as possible. If there are bumps, jumps or other gaps in your X-Axis tracks it can cause operational issues.

Please do not hammer the Aluminum tracks. Aluminum is a soft metal and if you hammer these tracks to install them with force you can end up with deformed tracks and they will require replacement.

This photo shows the result of hammering on the aluminum tracks.

DO NOT HAMMER THE ALUMINUM TRACKS.

Installing these tracks with care will help to ensure the longevity of your FarmBot and limit the wear on your motors.

For Genesis Bots, Step 1 of the installation process is the installation of the tracks: https://genesis.farm.bot/v1.5/FarmBot-Genesis-V1.5/tracks

Here is an example of a sturdy fixed raised bed where you can see the FarmBot will be able to operate for years to come. In this example the school used pressure treated lumber with a moisture barrier to protect against chemical leaching.